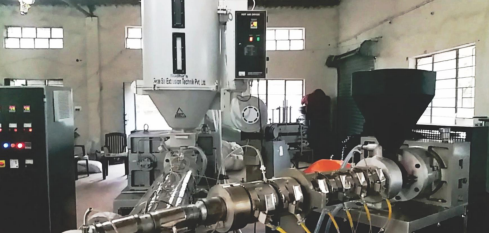

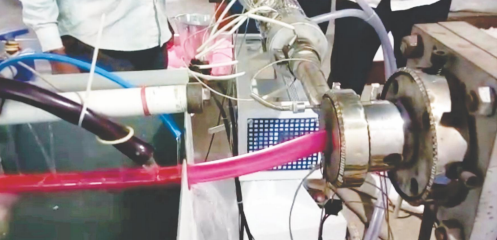

TWIN SCREW RPVC PIPE EXTRUSION MACHINERY LINES

Twin-screw extruder is that the classic machine used for the plastic extrusion process when two or more ingredients are mixed or Compounded. The method is best suited when extruding reactive polymeric materials.

Machine Advantages

- The twin-screw extruder has developed new models with higher torque, higher speed and lower consumption, and high-speed brings high productivity.

- Increase labor efficiency.

- When within the manufacture of masterbatch, it often requires to vary colors or to vary products if necessary.

- Know the conditions of the wearing parts timely.

Technical Specification

| Model | Extruder Drive | LD Ratio | Max Out Put (kg) | Pipe Range (mm) |

|---|---|---|---|---|

| SSET 52/18V | 11 KW AC | 18 : 1 | 100 - 120 | 16 – 110 |

| SSET 52/25V | 15 KW AC | 25 : 1 | 170 | 25 – 200 (4 Kg) |

| SSET 65/18V | 18 KW AC | 18 : 1 | 200 | 50 – 200 |

| SSET 65/22V | 30 KW AC | 22 : 1 | 250 | 50 – 250 |

| SSET 68/28V | 37 KW AC | 28 : 1 | 350 | 63 – 315 |

| SSET 90/22V | 56 KW AC | 22 : 1 | 450 | 90 – 450 |

| SSET 90/25V | 60 KW AC | 25 : 1 | 550 | 110 – 450 |

| SSET 92/28V | 75 KW AC | 28 : 1 | 700 | 200 – 600 |