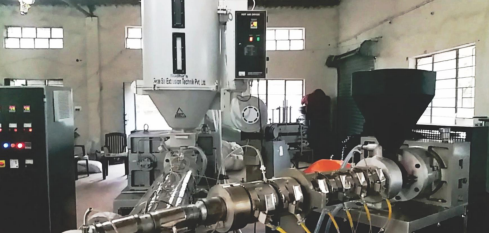

PPR-3 LAYER HDPE PIPE EXTRUSION MACHINERY LINES

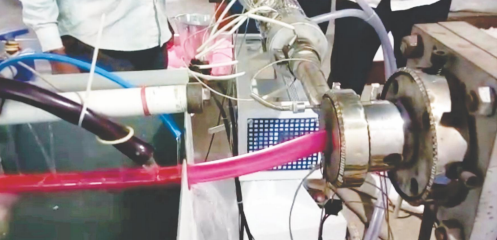

PPR-3 pipe is a straight and rigid cylindrical pipe, made of polypropylene random copolymer plastic, manufactured through a continuous extrusion process. They are typically offered in green or white, and range in size from 20 mm to 110 mm in outer diameter, making pipe walls thicker than PVC. PPR pipe comes with a range of connection fittings, parts, and accessories available for each pipe diameter.

Machine Advantages

- Screw & Barrel, PLC Control System and Spiral Type Die Head and other parts of High Speed PPR Pipe Plant are designed to bring optimum results and ensure better productivity results.

- Spiral type die head ensures stable wall thickness of PPR pipe even at high output.

- Energy efficient ensuring low power consumption.

- It is designed for an easy operation and performance optimization.

Technical Specification

| Model | Extruder Drive | LD Ratio | Max Output (kg) | Pipe Range (mm) |

|---|---|---|---|---|

| SSET 65 + 45 + 45 + 30 HDPE | 15 KW AC | 28 : 1 | 60 | 16 – 75 |

| SSET 65 + 45 + 45 + 30 HDPE | 20 KW AC | 28 : 1 | 100 | 16 – 110 |

| SSET 65 + 45 + 45 + 30 HDPE | 25 KW AC | 32 : 1 | 150 | 16 – 110 |

| SSET 75 + 50 + 50 + 30 HDPE | 55 KW AC | 30 : 1 | 200 | 19 – 200 |

| SSET 75 + 50 + 50 + 30 HDPE | 60 KW AC | 32 : 1 | 250 | 19 – 250 |

| SSET 75 + 50 + 50 + 30 HDPE | 110 KW AC | 35 : 1 | 300 | 50 – 300 |

| SSET 90 + 65 + 65 + 30 HDPE | 100 KW AC | 35 : 1 | 400 | 75 – 350 |

| SSET 110 + 65 + 65 + 40 HDPE | 160 KW AC | 35 : 1 | 600 | 110 – 630 |

| SSET 110 + 65 + 65 + 40 HDPE | 220 KW AC | 35 : 1 | 850 | 500 – 1000 |

| SSET 150 + 65 + 65 + 40 HDPE | 300 KW AC | 35 : 1 | 1000 | 600 – 1200 |