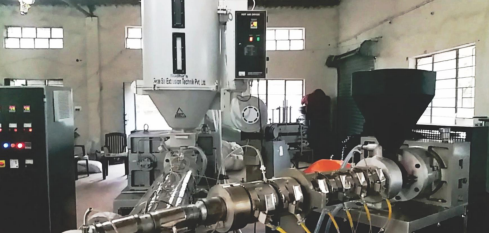

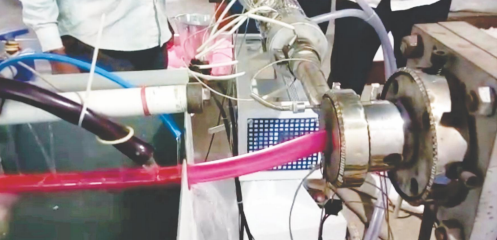

PLB DUCT HDPE PIPE EXTRUSION MACHINERY LINES

PLB HDPE Duct is manufactured using high grade of HDPE with inner layer of anti oxidant material and other suggested additives. The inner layer of PLB HDPE ducts is silicone coated which reduces friction between the OFC and the duct during the entire process of blowing the cable into the ducts, thus providing smooth installation.

Machine Advantages

- Offers a prominent advantage in terms of Environmental Stress Crack Resistance.

- Great Impact Resistance.

- Low Coefficient of Friction.

- Temperature Resistance.

- Crack proof finishing of the products.

- Light weight.

- No reaction to the water and thus cleaning can be done easily with just the water stream.

- High ability to Ultraviolet (UV) protection.

Technical Specification

| Model | Extruder Drive | LD Ratio | Max Output (kg) | Pipe Range (mm) |

|---|---|---|---|---|

| SSET 65 + 45 + 30 HDPE | 15 KW AC | 28 : 1 | 60 | 16 – 75 |

| SSET 65 + 45 + 30 HDPE | 20 KW AC | 28 : 1 | 100 | 16 – 110 |

| SSET 65 + 45 + 30 HDPE | 25 KW AC | 32 : 1 | 150 | 16 – 110 |

| SSET 75 + 50 + 30 HDPE | 55 KW AC | 30 : 1 | 200 | 19 – 200 |

| SSET 75 + 50 + 30 HDPE | 60 KW AC | 32 : 1 | 250 | 19 – 250 |

| SSET 75 + 50 + 30 HDPE | 110 KW AC | 35 : 1 | 300 | 50 – 300 |

| SSET 90 + 65 + 30 HDPE | 100 KW AC | 35 : 1 | 400 | 75 – 350 |

| SSET 110 + 65 + 40 HDPE | 160 KW AC | 35 : 1 | 600 | 110 – 630 |

| SSET 110 + 65 + 40 HDPE | 220 KW AC | 35 : 1 | 850 | 500 – 1000 |

| SSET 150+ 65 + 40 HDPE | 300 KW AC | 35 : 1 | 1000 | 600 – 1200 |