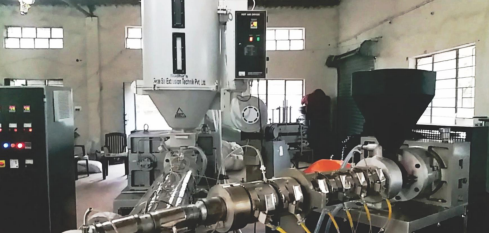

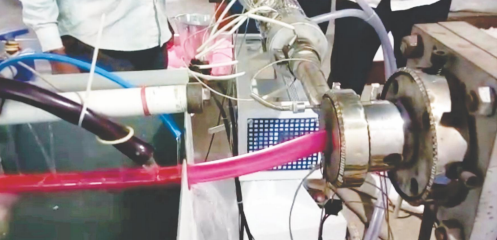

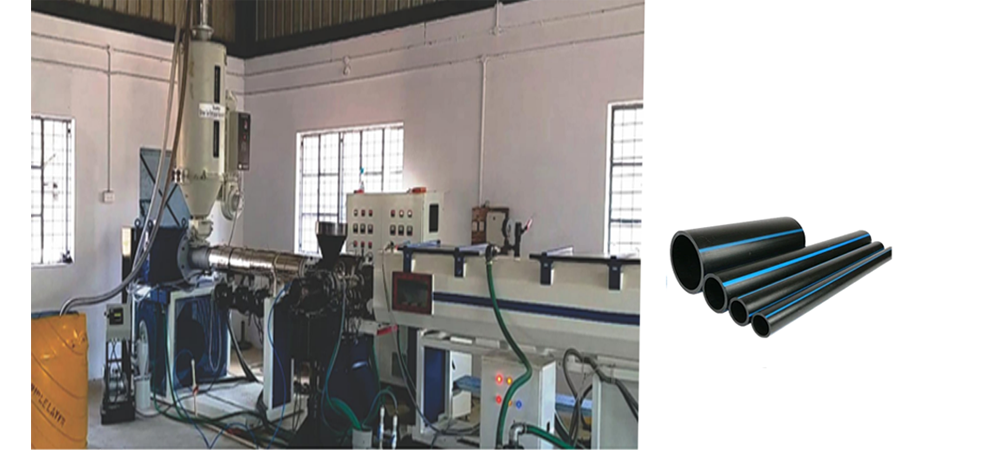

HDPE PIPE EXTRUSION MACHINERY LINES

HDPE Pipes are widely used for industrial applications such as industrial water transportation, coal handling in mines, chemical lines, agricultural and lift irrigation, and underwater pipelines and desalination plants. HDPE pipes owe their popularity to characteristics such as high tensile strength, durability, and lightweight.

Machine Advantages

- The Industry is widely used for sewage pipe in chemical industry, hospital, environmental protection and other industries.

- Agricultural Garden Project: Used for agricultural land, fruit and tea gardens and drainage of forest areas.

- Municipal engineering: used as drainage and sewage pipe.

- Road Engineering: Used as seepage and drainage pipe of railways and expressways.

Technical Specification

| Model | Extruder Drive | LD Ratio | Max Output (kg) | Pipe Range (mm) |

|---|---|---|---|---|

| SSET 65 HDPE | 15 KW AC | 28 : 1 | 60 | 16 - 75 |

| SSET 65 HDPE | 20 KW AC | 28 : 1 | 100 | 16 - 110 |

| SSET 65 HDPE | 25 KW AC | 32 : 1 | 150 | 16 - 110 |

| SSET 75 HDPE | 55 KW AC | 30 : 1 | 200 | 19 - 200 |

| SSET 75 HDPE | 60 KW AC | 32 : 1 | 250 | 19 - 250 |

| SSET 75 HDPE | 110 KW AC | 35 : 1 | 300 | 50 - 300 |

| SSET 90 HDPE | 100 KW AC | 35 : 1 | 400 | 75 - 350 |

| SSET 110 HDPE | 160 KW AC | 35 : 1 | 600 | 110 - 630 |

| SSET 110 HDPE | 220 KW AC | 35 : 1 | 850 | 500 - 1000 |

| SSET 150 HDPE | 300 KW AC | 35 : 1 | 1000 | 600 - 1200 |